Bowman provided engineering services for the detail engineering for the Heavy-Duty Truck Shop (HDTS) traffic area grading and a new truck wash rack to replace existing inadequate infrastructure. Scope of work included the following:

- System, mechanical, piping, and electrical design criteria and specification

- Instrumentation design and control philosophy and equipment list

- Hydrologic and hydraulic analysis to establish the hydrologic conditions and site drainage

- Grading and drainage plans and site layout with horizontal control plan for construction survey

- Demolition plan for the existing wash rack

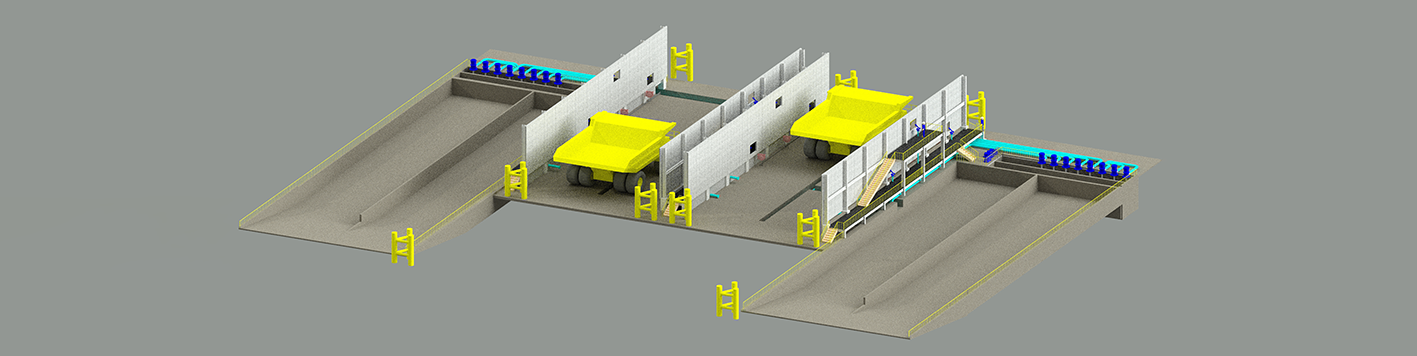

Prepared Truck Wash IFC Drawings, which included the following:

- Process flow diagrams (PFD)

- General arrangements of the wash bays including locations of equipment and utility features

- Concrete drawings of the wash bay slab, wash water settling pits, equipment/wall supports and utility equipment slabs

- Structural steel drawings for the service platform areas and the wash rack

- Walls

- Electrical single line diagrams, panel schedules, motor control panels, unit substation, raceway, cable and conduits schedule, lighting and grounding plans including connection to existing 4160 Volt power feed

- Piping & instrumentation diagrams (PID)

In addition, Bowman provided construction specifications, material and construction procedure, specifications for items related to the construction scope. Cost estimating for grading and truck wash construction scope targeting a +/- 10% accuracy, basis of estimate report, preliminary construction schedule and equipment vendor coordination.