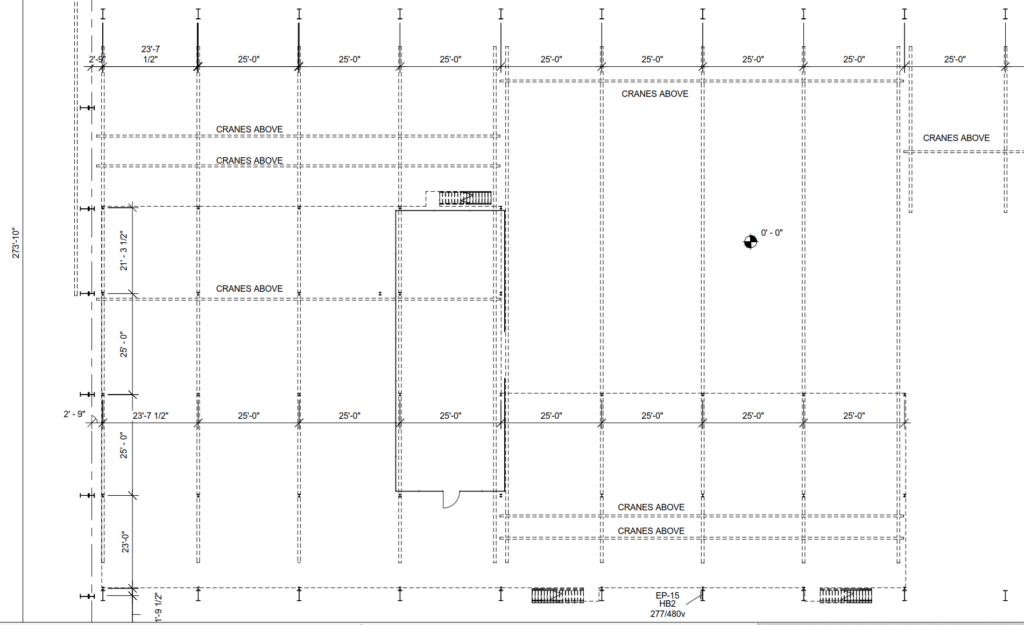

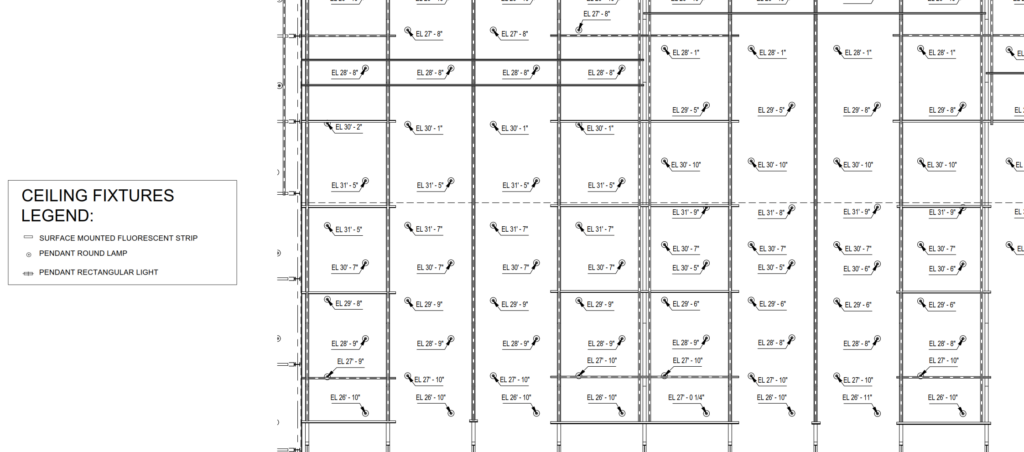

A modular building company purchased a massive manufacturing plant that needed to be reconfigured to meet their specific requirements. This facility, intended for the production of modular buildings, was well-suited for the task, but the client lacked existing as-built documents and a lighting study. Without this information, it was nearly impossible to begin space planning and layout for the plant. In addition to the scale of the facility, the project’s complexity stemmed from the need for a wide range of documentation in various formats—not only for the manufacturing plant’s construction but also to support the work of several consultants hired by the client.

Bowman’s 3D laser scanning, drone intelligence and modeling teams collaborated with the client, its vendors and consultants to create a variety of documents, ensuring the client knew exactly what they were working with.

Process

The manufacturing floor was scanned thoroughly, producing multiple Revit renderings. The drone pilot captured photos and videos, including a 360-degree video, enabling the client and vendors to remotely view and analyze the property.

Results

With the 3D scans and drone footage, Bowman was able to produce:

- A comprehensive 3D Revit model

- 2D CAD drawings

- 3D STEP model

- 2D PDFs

- Interior 360 inspection video

- Interior crane inspection photos

The final Revit model, floor plan and elevations laid the foundation for outfitting a state-of-the-art manufacturing plant. As shown in the renderings, the documentation provides a clear, accurate and detailed view of the entire space.